Products

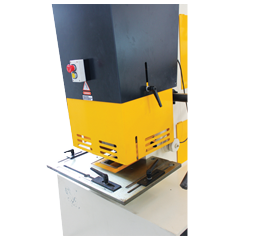

Twin Hydro - Dual Op

STANDARD MUTLI STEEL WORKER FEATURES

Dupunching.pngal Work StationMulti – Purpose

Full Steel Body Fabricated Structure manufactured with Prime Plates

Robust Welded and Bolted Frame for Extra Durability

Minimal Deflection Design

Full Tonnage throughout Stroke or Cycle

Overload Protection

Meets or Exceeds OSHA regulations for Safety

Guarding to Individual Specifications with E – Stop Circuits

IEC rated Electric Components

JIC / NFPA standard Components

Wide Variety of Tools and Dies as Options to choose from

Adjustable Magnetic Lamp for Enhanced Vision at all Work Stations

Electric Stroke Control

E5- SERIES FEATURES

Hydraulic Hold Downs for Angle StationHydraulic Hold Downs for Plate Shearing Station

Infra Red Safety Beam Censors at the Plate Shearing Station

Oil Cooler

Oil CoolerTower Light Indication

Rest All Features are same as Standard Machines.

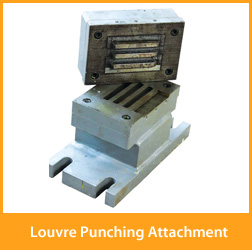

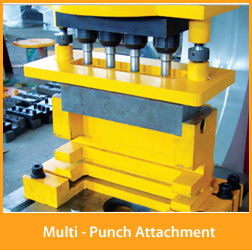

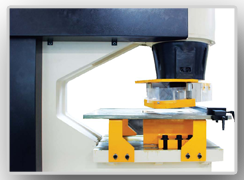

PUNCHING STATION

Large Machined Gauge Table with Scales and Guides Bars for X & Y position

T – Slot Bed Plate for Easy Clamping of Dies

Heavy Duty ‘Swing Away – Clear View’ Stripper

Quick Change Nut for Punch and Other Dies

Comes with Extended Table which can be easily removed to Punch in Angles, Channels and Other Profiles.

An Emergency Stop and Jog Up Button is Fitted at the Punching Station for Operator Safety and Convenience for Die Setting

ANGLE CUTTING STATION

Blades are Four Sided and can be easily rotated and re-installed

Hydraulic Clamping for Angle results in Time Saving and Secure Clamping.

Hydraulic Clamping gives a Clean, Square, Burr Free cut for the Angles.

Hydraulic Hold Downs Automatically adjusts the Pressure and clamps Angles of Various Sizes and Thickness

Hydraulic Hold Downs are Inter-locked with the Cutter Beam such that the cutting does not start till the Hold Downs fully clamps the Angle Bar.

PLATE SHEARING STATION

Blades are Four Sided and can be easily rotated and re-installed

Machined Table, Adjustable Guides with Angle / Tapper Shearing Marking on the Bed Plate

Hydraulic Clamping for Plate Shearing results in Time Saving and Secure Clamping of the work piece.

Hydraulic Clamping gives a Clean, Square, Burr Free cut for the Steel Plates, similar like Hydraulic Shearing Machines.

Hydraulic Hold Downs Automatically adjusts the Pressure and clamps Sheets of Various Sizes and Thickness.

Hydraulic Hold Downs are Inter-locked with the Cutter Beam such that the cutting does not start till the Hold Downs fully clamps the Steel Plate.

Infra – Beam Safety Censors are installed for the Operator Safety in order to prevent any mishap on the machine. The machine will stop if anything cuts the Beams preventing any Accident to occur resulting in Operator Safety.

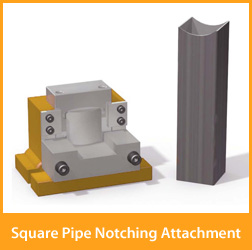

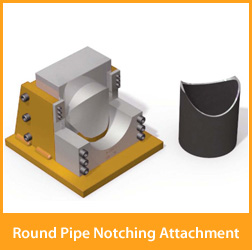

NOTCHING STATION

Comes with Standard U – Notching Blades

Machined Gauge Table with Scales and Guides Bars for X & Y position

T – Slot Bed Plate for Easy Clamping of Dies

An Emergency Stop and Jog Up Button is Fitted at the Notching Station for Operator Safety and Convenience for Die / Blade Clearance Settings

V- Notching Blades can be easily Installed and are available as an Option

ROUND / SQUARE BAR CUTTING STATION

Easy Manual Adjustable Hold Down for Standard Round / Square Bar Cutting

Quick and Easy change of Blades.

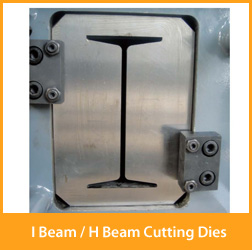

Easy Change of Optional C – Channel / I – Beam / H – Beam Cutting Blades used for Structural Fabrication, in this same Aperture.

TOUCH AND CUT ELECTRICAL BACK GAUGE

1 Mtr. Length Back Stop with Electrical Touch and Cut Feature.

Is Adjustable and can be aligned to all Cutting stations.

Automatic Single Stroke once the Gauge is Cut / Touched with the Work Piece

EXTRA THROAT DEPTH WITH LARGE GAUGE TABLE

Our XT – Models comes with Xtra Throat Depth

Large machined Gauge Table

Table is Equipped with Scales and Guides

TOWER LIGHT

indicates on the working of the machines on different modes.

Comes in our E5 - Series.

OIL COOLER

Comes in all our E5 Series

Maintains the Temperatures of Hydraulic Oil and prevents the machines to get Over Heated in longer running, thus making the running troublefree.

Table is Equipped with Scales and Guides

Stations |

Specifications |

MSW - 65 |

MSW - 85 |

MSW - 120 |

MSW - 175 E |

MSW - 220 E |

MSW - 275 E |

PUNCHING

|

Punching pressure Ton Punching pressureMetric Ton |

65 59 |

85 78 |

120 110 |

175 160 |

220 200 |

275 250 |

Diameter * Max Thickness |

25x20 |

33x20 |

38x25 |

30 x 32 |

42 x 35 |

45 x 40 |

|

Diameter * Thickness |

40x11 |

40x16 |

40x20 |

40 x 30 |

40 x 32 |

40 x 40 |

|

Max Thickness * Diameter |

110x3 |

110x4 |

110x5 |

125 x 5 |

125 x 6 |

125 x 7 |

|

Stroke Length |

70 |

90 |

100 |

100 |

110 |

110 |

|

No. of Strokes Per/Min on Full Range No. of Stroke Per/Min on 20mm Stroke |

10 25 |

8 25 |

8 25 |

8 25 |

8 25 |

8 25 |

|

Throat (ST - Standard Throat) |

315 |

355 |

400 |

500 |

--- |

--- |

|

(XT - Xtra Throat)* |

600 |

600 |

600 |

600 |

600 |

600 |

|

Work Height |

1030 |

1080 |

1110 |

1130 |

1110 |

1110 |

|

STEEL BAR SHEAR |

Round Bar |

45 |

50 |

55 |

65 |

75 |

85 |

Square Bar |

40 x 40 |

45x45 |

50x50 |

55 x 55 |

65x65 |

65x65 |

|

L - ANGLE SHEAR |

Angle Section (90 Degree) |

120x120x12 |

150x150x14 |

150x150x16 |

180x180x18 |

200x200x18 |

200x200x20 |

Angle Section(45 Degree) |

70 x 8 |

80x8 |

80x10 |

80 x 10 |

100x10 |

120x10 |

|

SHEET METAL SHEAR (PLATE SHEAR)

|

Length x Max. Thickness |

300 x 20 |

380x20 |

380x25 |

380 x 30 |

400x35 |

450x40 |

Max. Length x Thickness |

375 x 12 |

480x15 |

600x15 |

600 x 20 |

700x25 |

750x30 |

|

Blade Length |

380 |

485 |

610 |

610 |

710 |

765 |

|

Strength of Steel Plates (N/m㎡) No. of Hydraulic Hold Downs |

≤ 450 3 |

≤ 450 3 |

≤ 450 4 |

≤ 450 5 |

≤ 450 7 |

≤ 450 7 |

|

Working Height |

900 |

900 |

900 |

875 |

875 |

875 |

|

U - NOTCHING

|

Thickness |

10 |

13 |

13 |

16 |

18 |

18 |

Length |

100 |

100 |

100 |

120 |

120 |

120 |

|

Width |

45 |

52 |

60 |

60 |

60 |

60 |

|

Depth |

90 |

90 |

90 |

110 |

110 |

110 |

|

Work Table Height |

800 |

800 |

800 |

750 |

750 |

750 |

|

V-NOTCHING* |

90x90x10 |

100x100x12 |

105x105x13 |

105x105x16 |

105x105x18 |

105x105x18 |

|

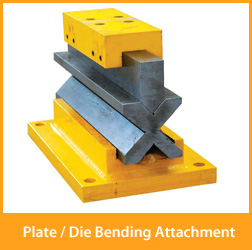

BAR BENDING* |

Length x Thickness |

250x15 |

250x20 |

250x22 |

250x25 |

250x25 |

250x25 |

SHEET BENDING * |

Length x Thickness |

400x2 |

500x4 |

700x3 |

700x4 |

700x5 |

700x5 |

C - CHANNEL * |

Height x Width |

120x60 |

160x75 |

200x90 |

250x125 |

300x125 |

320x130 |

I - BEAM * |

Height x Width |

120x60 |

160x75 |

200x90 |

250x125 |

300x125 |

320x130 |

MOTOR (kW) / (HP) |

400 - 440 V / 3Ph / 50Hz |

5.5KW/7.5HP |

7.5KW/10HP |

11KW/15HP |

11KW/15HP |

15KW/20HP |

18.5KW/25HP |

NET WEIGHT (KGS) / (Lbs.) |

ST 'E' SERIES XT 'E ' SERIES |

1800 / 4000 2100 / 4630 |

2485 / 5480 2890 / 6370 |

4200 / 9260 4500 / 9920 |

5800 / 12786 6600 / 14550 |

---- 9000 / 19900 |

---- 12500/27560 |

GROSS WEIGHT (KGS) / (Lbs.) |

ST 'E' SERIES XT 'E ' SERIES |

2000 / 4400 2250 / 4960 |

2665 / 5875 3140 / 6925 |

4450 / 9810 4775 / 10530 |

6150 / 13660 7000 / 15430 |

---- 9650 / 21275 |

---- 13200/29100 |

OIL TANK CAPACITY |

(Ltrs.) / (Gallons) |

85 /22 |

110 / 30 |

180 / 48 |

220 / 60 |

250 / 66 |

250 / 66 |

MACHINE DIMENSIONS (L x W x H) |

ST 'E' SERIES XT 'E ' SERIES |

1700x900x1880 2000x900x1880 |

2000x950x2040 2250x950x2040 |

2350x1000x2200 2550x1000x2200 |

2750x1150x2280 2850x1150x2280 |

---- 2950x1600x2400 |

---- 3200x1760x2450 |

VOLUME OF MARITIME PACKING |

ST 'E' SERIES XT 'E' SERIES |

2.87 3.38 |

4.16 4.65 |

5.17 5.61 |

7.2 7.5 |

---- 11.32 |

---- 13.8 |

Stations |

Specifications |

MSW - 65 |

MSW - 85 |

MSW - 120 |

MSW - 175 E |

MSW - 220 E |

MSW - 275 E |

PUNCHING

|

Punching pressure Ton Punching pressureMetric Ton |

65 59 |

85 78 |

120 110 |

175 160 |

220 200 |

275 250 |

Diameter * Max Thickness |

1' x 3/4' |

1 1/4' x 3/4' |

1 1/2' x 1' |

1 1/8' x 1 1/4' |

1 5/8' x 1 3/8' |

1 3/4' x 1 5/8' |

|

Diameter * Thickness |

1 5/8' x 3/8' |

1 5/8' x 5/8' |

1 5/8' x 3/4' |

1 5/8' x 1 1/8' |

1 5/8' x 1 1/4' |

1 5/8' x 1 5/8' |

|

Max Thickness * Diameter |

4 3/8' x 1/8' |

4 3/8' x 1/4' |

4 3/8' x 1/4' |

4 7/8' x 1/4' |

4 7/8' x 1/4' |

4 7/8' x 1/4' |

|

Stroke Length |

3' |

4' |

4' |

4' |

4' |

4' |

|

No. of Strokes Per/Min on Full Range No. of Stroke Per/Min on 20mm Stroke |

10 25 |

8 25 |

8 25 |

8 25 |

8 25 |

8 25 |

|

Throat (ST - Standard Throat) |

12' |

14' |

16' |

20' |

--- |

--- |

|

(XT - Xtra Throat)* |

24' |

24' |

24' |

24' |

24' |

24' |

|

Work Height |

41' |

43' |

45' |

45' |

44' |

44' |

|

STEEL BAR SHEAR |

Round Bar |

1 3/4' |

2' |

2 1/8' |

2 1/2' |

3' |

3 1/8' |

Square Bar |

4 1 5/8' x 1 5/8' |

2' x 2' |

2' x 2' |

2 1/8' x 2 1/8' |

2 1/2' x 2 1/2' |

2 1/2' x 2 1/2' |

|

L - ANGLE SHEAR |

Angle Section (90 Degree) |

4 3/4' x 4 3/4' x 1/2' |

6' x 6' x 1/2' |

6'x 6' x 5/8' |

7 1/8' x 7 1/8' x 3/4' |

8' x 8' x 3/4' |

8' x 8' x 7/8' |

Angle Section(45 Degree) |

2 3/4' x 1/3' |

3 1/8' x 1/3' |

3 1/8' x 3/8' |

3 1/8' x 3/8' |

3/8'0 x 3/8' |

4 3/4' x 3/8' |

|

SHEET METAL SHEAR (PLATE SHEAR)

|

Length x Max. Thickness |

12' x 3/4' |

15' x 3/4' |

15' x 1' |

15' x 1 1/8' |

16' x 1 3/8' |

18' x 1 5/8' |

Max. Length x Thickness |

15' x 1/2' |

19' x 5/8' |

24' x 5/8' |

24' x 3/4' |

28' x 1' |

30' x 1 1/8' |

|

Blade Length |

15 1/4' |

19 3/8' |

24 3/8' |

24 3/8' |

28 3/8' |

30 5/8' |

|

Strength of Steel Plates (N/m㎡) No. of Hydraulic Hold Downs |

≤ 450 3 |

≤ 450 3 |

≤ 450 4 |

≤ 450 5 |

≤ 450 7 |

≤ 450 7 |

|

Working Height |

36' |

36' |

36' |

35' |

35' |

35' |

|

U - NOTCHING

|

Thickness |

3/8' |

1/2' |

1/2' |

5/8' |

3/4' |

3/4' |

Length |

4' |

4' |

4' |

4 3/4' |

4 3/4' |

4 3/4' |

|

Width |

1 3/4' |

2' |

2 3/8' |

2 3/8' |

2 3/8' |

2 3/8' |

|

Depth |

3 1/2' |

3 1/2' |

3 1/2' |

4 3/8' |

4 3/8' |

4 3/8' |

|

Work Table Height |

32' |

32' |

32' |

30' |

30' |

30' |

|

V-NOTCHING* |

3 1/2' x 3 1/2' x 3/8' |

4' x 4' x 1/2' |

4 1/8' x 4 1/8' x 1/2' |

4 1/8' x 4 1/8' x 5/8' |

4 1/8' x 4 1/8' x 3/4' |

4 1/8' x 4 1/8' x 3/4' |

|

BAR BENDING* |

Length x Thickness |

10' x 1/2' |

10' x 3/4' |

10' x 7/8' |

10' x 1' |

10' x 1' |

10' x 1' |

SHEET BENDING * |

Length x Thickness |

16' x 1/12' |

20' x 1/6' |

28' x 1/8' |

28' x 1/6' |

28' x 1/5' |

28' x 1/5' |

C - CHANNEL * |

Height x Width |

4 3/4' x 2 3/8' |

6 1/4' x 3' |

8' x 3 1/2' |

10' x 4 7/8' |

12' x 4 7/8' |

13' x 5 1/8' |

I - BEAM * |

Height x Width |

4 3/4' x 2 3/8' |

6 1/4' x 3' |

8' x 3 1/2' |

10' x 4 7/8' |

12' x 4 7/8' |

13' x 5 1/8' |

MOTOR (kW) / (HP) |

400 - 440 V / 3Ph / 50Hz |

5.5 KW / 7.5 HP |

7.5 KW / 10 HP |

11 KW / 15 HP |

11 KW / 15 HP |

15 KW / 20 HP |

18.5 KW / 25 HP |

NET WEIGHT (KGS) / (Lbs.) |

ST 'E' SERIES XT 'E ' SERIES |

1800 / 4000 2100 / 4630 |

2485 / 5480 2890 / 6370 |

4200 / 9260 4500 / 9920 |

5800 / 12786 6600 / 14550 |

---- 9000 / 19900 |

---- 12500/27560 |

GROSS WEIGHT (KGS) / (Lbs.) |

ST 'E' SERIES XT 'E ' SERIES |

2000 / 4400 2250 / 4960 |

2665 / 5875 3140 / 6925 |

4450 / 9810 4775 / 10530 |

6150 / 13660 7000 / 15430 |

---- 9650 / 21275 |

---- 13200/29100 |

OIL TANK CAPACITY |

(Ltrs.) / (Gallons) |

85 ltrs / 22 Gal |

110 ltrs / 30 Gal |

180 ltrs / 48 Gal |

220 ltrs / 60 Gal |

250 ltrs / 66 Gal |

250 ltrs / 66 Gal |

MACHINE DIMENSIONS (L x W x H) |

ST 'E' SERIES XT 'E ' SERIES |

68' x 36' x 75' 80' x 36' x 75' |

86' x 38' x 82' 96' x 38' x 82' |

94' x 40' x 88' 102'x40'x88' |

110'x46'x91' 114'x46'x91' |

---- 118'x64'x96' |

---- 128'x70'x98' |

VOLUME OF MARITIME PACKING |

ST 'E' SERIES XT 'E' SERIES |

2.87 3.38 |

4.16 4.65 |

5.17 5.61 |

7.2 7.5 |

---- 11.32 |

---- 13.8 |